Product Description

Air Compressor Gear for Atlas Copco

Product Description

More Air Compressor Gear for Altas Copco

1092012700

1092571011

1092571012

1092003639

1092003640

1092571038

1092571037

1092571041

1092571042

1614933000

1614933100

1621240500

1621240600

1621241100

1621241200

1621241700

1621242300

1621242400

1621242500

1621242600

1621242700

1613898100

2252762300

1622311056

1613853700

1613898300

1621052605

1613844400

1622311074

1613867200

1623398700

225710841

1616563500

1622311040

1623396100

1621052406

1616563900

225710843

1623398300

225710865

22571 0571

1623326500

1613818000

1623399200

1623103200

1622461350

1622461342

1291001476

1621052602

1622311026

1622311571

1623393600

1619700301

1616568200

1622461324

1616563300

1621906300

1614932900

1614932200

1613965600

1616623801

1616642400

290657100

1616623418

1616620709

1604910700

2252747500

1616562900

1257127400

1616539600

1614934400

1257115600

1613965000

1616555900

1614931100

1614932800

1616641700

1614935710

1616623804

165716100

1616623807

1257126400

1623110900

2906059000

1614681308

1604250800

1202675700

13257116

2252904300

1616642300

1614681303

1616556700

1616648934

1614968200

1616556100

1616620602

1257127500

2906571500

1616570500

1202634802

1202634205

2252576200

1616623523

1623106700

1616622001

1616641800

1616623619

1616565200

1616623802

1621906200

1621906400

1613855700

1614930900

1615639300

1621487700

1616620608

1616623808

2254096406

1617774181

1202634304

1202676500

1614933200

16215713

1202676200

225571480

1621242500

1616620815

1613963900

1621413900

1202676300

1092019800

1617774091

1613897900

1257126100

1614931300

1616642504

1614934500

16215718

1614967500

2254391780

1621242200

1622118210

1616648911

1616491102

1621487880

161662571

1613965700

1606127906

1621052514

1615539200

1616555300

162257171

1616648905

1616623413

2253825600

1257126200

1616620804

2254114901

162257171

1616543300

1616539800

1616648829

1616613915

2254115001

1616564602

1623405900

2255113300

1616623414

1202676900

1623106400

2252747600

1626215202

1614681209

2254817703

1616565780

161662571

2906056900

1614930800

1257114900

2253825700

1616565710

13257110

1613877400

1613964800

1614681321

1623110800

1616562800

1616555200

2255012500

1616613921

2252179400

1616565900

2253763000

1623103300

2252922900

161662571

1616444400

165719780

1257127200

165710400

1257196600

1614967300

1621432000

1616623704

1621052511

162257100

1202675600

1616620805

1614931200

1616623720

290657100

1257196700

1613823402

1604054500

1616555600

1614967600

2252747400

1622000700

2253763100

1616551400

1621927700

2252904400

1614681302

1616623504

1623109600

1616575900

1614681409

1616623613

1608095718

1623393100

2252576500

1616623618

165711400

1616620802

1614967900

2254817503

1613964200

1616623901

1616620604

1613964300

2906042300

1621052506

225415710

1613963400

1614968000

1614933700

16215717

1616623521

1616648923

1616574000

1613963700

1257127300

1257127600

1616620721

165716300

1623326100

1621052405

2254096202

1616623420

1202634305

1616620809

1613963500

1614930500

1257159800

1621793900

1616565300

225457100

2254115002

1614933300

2254817601

1621488280

1616642502

1616623902

1616623417

1613897902

1616623520

1621243000

2906030400

1320409571

2252904500

1621052507

1616620612

1616563100

1616539700

1614967200

1614968100

1616648908

1613964700

2906571900

1614967100

1616555800

1622003800

1614930600

1606128006

1614967800

2254100300

1616612410

1613835710

2235578600

1616642501

1202634204

1614681230

1614967700

1616613902

1613844600

2255012400

1613886500

1616623617

225718067

1202633802

1616620720

1616556600

2254817603

1616648929

1613964400

2252667300

1622197180

1616620614

2252576300

1616623422

1621488200

1622273080

1621211800

1623106500

1616623509

1613835900

1614932300

1615539100

1617773995

1614681304

1202672900

1616564100

1616620806

2906571800

1614967000

1616620610

1616623703

1612517000

1614968300

1617796180

1614933500

1613964000

1614932700

1622003400

1614931500

2252895000

162205710

1623396700

2255096000

225457100

1604912200

225457100

2255096280

1616563000

1616620704

16571100

1623393000

1616612414

1621052504

1621244200

1613965400

225457100

1621244300

2254171900

1613964100

1616540900

1202634406

1622003300

1613965500

1616623506

1616648920

2252904480

1613964500

1621052513

1616612415

2910019500

1614931000

2253763200

2254817501

1614681412

2157176900

1621242600

1616642100

1604033000

1202634303

1616613916

1616613919

1616613922

1616623701

1621413800

1621052503

1617774083

1622369214

2252894700

1202635404

1616564000

1615456300

2252923000

16215711

1613276100

1614968500

1202676400

1614935710

1257115000

1623109800

1614968400

1614933100

1257196200

225718068

1614933000

1616656302

1616648915

1616623416

165711700

1616648910

1616648936

1616642200

1621241700

1616556000

2254100000

1616620801

1614930400

1613963800

16231 0571 0

1616623705

1614933600

1614967400

1616576000

162315710

1614933400

1613965100

1614930000

1616648921

162257171

2157177000

165711600

1616623803

1257126300

2252904200

2906065800

1621242900

1613816300

16231 0571 0

16215710

1613877500

1617773991

1621884947

1616555400

2253762900

1621244000

1614930300

1616539900

1617773980

2254817701

225457100

1616620619

225457100

1613914000

1257159900

1092017500

1616565100

165712680

1614932600

2252774700

1202634405

1621927800

1616612419

1257118500

2254096402

2157175100

1614681309

1202601600

1614681317

1614681301

1614930700

2254096302

2252747300

2906040300

1616622101

1621579103

16215715

1621242100

1613963600

1616571000

2901154800

161662 0571

2252179300

2205262551

1621241800

1616555700

165711101

161662 0571

2906571200

1621657802

1613877300

2906026900

1257127100

2255096100

1257118400

290657100

162155714

2252895080

1257196300

1621052409

1616648810

1616555500

1901957143

1616623502

1092108800

1092108000

1092571019

1092106800

10921 0571 0

1092571042

1092057181

1092002669

1092001800

1092001798

1092001797

1092001795

1092001793

1092001792

1092001789

1092001787

1092001785

1092571701

1092571646

1092571641

1092571645

1092571627

1092571626

1092571635

1092004976

1092004974

1092003633

1092004969

1092571861

1092571858

1092571871

1092571827

1092571862

1092571828

1092571825

1092571857

1092571655

1092571656

1092571936

1092571935

1092571934

1092571929

1092571928

1092571927

1092571872

1092571930

1092571926

1092571925

1092571917

1092571944

1092571933

1092571943

1092571946

1092571945

1092571940

1092571941

1092571939

1092571966

1092571942

1092571965

1092571968

1092571967

1092571955

1092571950

1092571949

1092571983

1092571984

1092571956

1092571003

1092571004

1092571972

1092571971

1092571982

1092571981

1092571039

1092571031

1092571041

1092571040

1092571016

1092571015

1092571571

1092106700

1092104900

1092104800

10921 0571 0

109215710

1092109800

1092109600

109215710

109215710

1092106900

1092001794

1092001791

1092001788

1092001790

1092001786

1092003054

1092001801

1092002685

1092001799

1092001796

1092571636

1092571625

1092004668

1092004973

1092003634

1092003055

1092571702

1092571642

1621242800

1621243200

1621243300

1621243900

162315710

1623108000

1092106900

1625001737

1625001709

165711180

1625001701

1625001730

1625001789

1622699371

1625001750

1625001753

1625001741

165718682

1625001704

1603068114

1320704207

1625001732

1626566180

1625001735

1625001731

1625001702

30038 0571 8

1625001747

1625001708

1625001727

162657180

1320703419

1625001705

1625001756

1625001710

1625001745

2254100080

1625001723

1622698885

1625001720

1622599194

1625001788

1625001700

162557105

1625001950

1625001729

1622662068

1625001744

1092004668

1625001703

1092004969

1625001743

1625001734

1625001746

162645710

1625001706

162557127

1625001755

1622599181

1625001751

1625001742

1625001733

162557112

1625001713

1625001754

1625001752

162657181

1625001736

1625001716

1625001749

1625001748

1626531480

1625001715

1625001722

pack your goods?

There is 3 kinds of ways to packed the goods, which depends on your requirement

1. Packed with original package

2. Packed with your design package

3. Packed with our blank package, below is the example for referenc

Air Compressor Gear for Altas Copco FAQ

Q1: How can I get the quotation?

A: you can advise us the part number for checking, and we will quote to you soon by email

Q2: What kind of ways for transportation ?

A:In general by air, sea or Express.(like DHL,Fedex,TNT,etc.)

Q3: How do I know the quality of productions?

A:We have a strict series of quality control, and we have perfect after service system, which can help you to solve the problem soon

Q4: If i want to change model,size,package,etc. How can I do?

A:You can contact us by or mail, and we will revise according to your requirement

Q5: What is the terms of payment ?

A: T/T, Western Union, paypal

| Lubrication Style: | Oil-free |

|---|---|

| Cooling System: | Air Cooling |

| Power Source: | AC Power |

| Cylinder Position: | Vertical |

| Structure Type: | Closed Type |

| Installation Type: | Stationary Type |

| Customization: |

Available

| Customized Request |

|---|

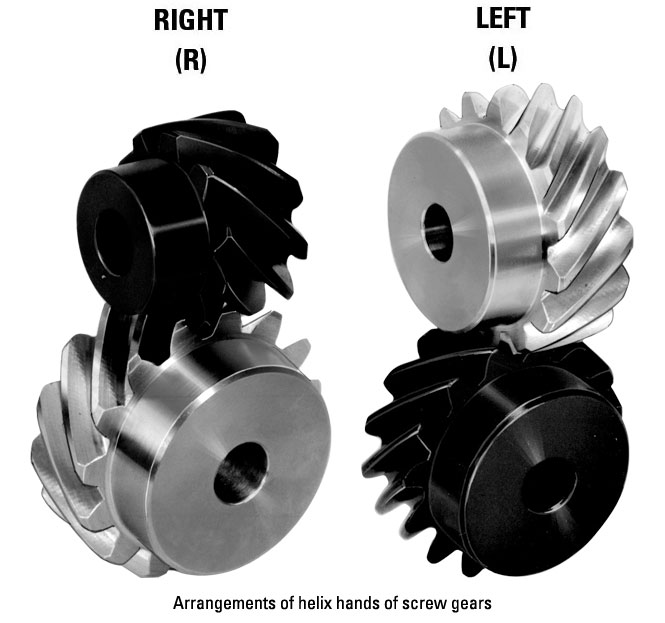

What is the purpose of using screw gears in machinery?

Screw gears, also known as worm gears, serve various purposes in machinery and mechanical systems. They offer unique advantages that make them suitable for specific applications. Here’s a detailed explanation of the purposes and benefits of using screw gears:

- High Gear Reduction: One of the primary purposes of using screw gears is to achieve high gear reduction. Screw gears provide a significant reduction ratio, allowing for the conversion of high-speed, low-torque input to low-speed, high-torque output. This makes them ideal for applications that require precise control over torque and rotational speed, such as lifting heavy loads, positioning systems, and machinery with high torque requirements.

- Precise Positioning: Screw gears enable precise positioning and control of linear or rotary motion. The fine-pitch threads on the worm and the corresponding worm wheel teeth allow for accurate and controlled motion. This feature makes screw gears suitable for applications that require precise positioning, such as robotics, automation, and machinery that performs intricate movements or adjustments.

- Self-Locking: Screw gears have a self-locking property, which means that the gear mechanism remains fixed in position even when no external force is applied. The friction between the screw threads and the worm wheel prevents the system from backdriving or rotating unintentionally. This self-locking feature eliminates the need for additional braking mechanisms or external locks, making screw gears advantageous in applications where holding a position is essential for safety and stability.

- Compact Design: Screw gears have a compact design that makes them suitable for applications with limited space. The worm and worm wheel arrangement allows for efficient power transmission in a compact layout, enabling the integration of screw gears in machinery and systems where space is a constraint. This compact design also simplifies installation and reduces the overall footprint of the equipment.

- Quiet and Smooth Operation: Screw gears operate with reduced noise and vibration compared to other gear types. The helical nature of the threads and the sliding/rolling contact between the worm and worm wheel result in a smooth and gradual meshing motion. This smooth operation contributes to quieter machinery, making screw gears desirable in applications where noise reduction is important, such as in residential environments, audio equipment, and precision instruments.

- High Shock Load Resistance: Screw gears are known for their ability to handle shock loads effectively. The helical shape of the threads and the larger contact area between the worm and the worm wheel distribute the load more evenly, reducing the risk of sudden failures or damage due to shock or impact loads. This shock load resistance makes screw gears suitable for applications that involve sudden changes in load or external forces.

- Reliability and Durability: Screw gears are recognized for their reliability and durability. The simplicity of their design, with fewer moving parts, reduces the likelihood of mechanical failures. Additionally, the self-locking feature minimizes the chances of unwanted movement or slippage. When properly lubricated and maintained, screw gears can have a long service life and require minimal maintenance, contributing to the overall reliability of machinery.

- Wide Range of Applications: Screw gears find application in various industries and machinery types. They are utilized in manufacturing equipment, robotics, medical devices, automotive systems, elevators, material handling machinery, and many other systems that require precise control, high torque, compactness, and reliable power transmission.

The purpose of using screw gears in machinery is to provide efficient power transmission, precise positioning, high torque multiplication, self-locking capabilities, and reliable operation. These features make screw gears a valuable component in numerous applications, enhancing performance, safety, and overall functionality of machinery and mechanical systems.

Can screw gears be used in heavy-duty machinery and equipment?

Yes, screw gears, also known as worm gears, can be used in heavy-duty machinery and equipment. Screw gears offer several advantages that make them suitable for such applications. Here’s a detailed explanation of using screw gears in heavy-duty machinery and equipment:

- High Load Capacity: Screw gears are known for their high load-carrying capacity. The helical design of the gear teeth allows for distributed contact between the worm gear and the worm wheel, enabling them to handle significant loads. This makes screw gears well-suited for heavy-duty applications where large forces and torque need to be transmitted.

- Self-Locking Capability: Screw gears have a self-locking feature, which means they can hold position without the need for additional braking mechanisms. In heavy-duty machinery and equipment, this self-locking capability can be advantageous, especially when it is necessary to prevent the load from moving or to maintain position under static or dynamic loads.

- Compact Design: Screw gears have a compact design, which allows for space-saving installations in heavy-duty machinery and equipment. Their axial orientation and the ability to achieve high gear ratios in a single stage contribute to their compactness. This is particularly beneficial in applications where space is limited or where a compact gear system is desirable.

- Smooth and Quiet Operation: Screw gears generally operate with low noise and vibration levels. The helical nature of the gear teeth engagement results in smooth and continuous contact, reducing noise and minimizing vibrations. This is advantageous in heavy-duty machinery and equipment, where quiet operation is often desired to enhance operator comfort and minimize the impact on surrounding components.

- High Gear Reduction Ratios: Screw gears can achieve high gear reduction ratios in a single stage, which is beneficial in heavy-duty applications that require significant speed reduction or torque multiplication. This eliminates the need for multiple gear stages or additional components, simplifying the gear system design and reducing the overall complexity.

- Durability and Longevity: Screw gears are known for their durability and long service life. When properly designed, manufactured, and maintained, they can withstand heavy loads, operate under challenging conditions, and exhibit good resistance to wear and fatigue. This makes them suitable for heavy-duty machinery and equipment that operate in demanding environments.

- Compatibility with Various Materials: Screw gears can be manufactured from different materials to suit specific application requirements. This flexibility allows for compatibility with various other components and materials used in heavy-duty machinery and equipment. The choice of materials can be tailored to factors such as strength, wear resistance, and compatibility with lubricants or operating conditions.

In summary, screw gears can be effectively used in heavy-duty machinery and equipment due to their high load capacity, self-locking capability, compact design, smooth operation, high gear reduction ratios, durability, and compatibility with different materials. By considering the specific requirements of the application and employing proper design and manufacturing practices, screw gears can provide reliable and efficient power transmission in heavy-duty scenarios.

What are the applications of screw gears?

Screw gears, also known as worm gears, find a wide range of applications across various industries. Their unique characteristics make them suitable for specific purposes where precise motion control, torque multiplication, or holding position is required. Here is a detailed explanation of the applications of screw gears:

- Machinery and Manufacturing: Screw gears are commonly used in machinery and manufacturing equipment. They are employed in gearboxes and power transmission systems to achieve speed reduction or torque multiplication. They can be found in conveyor systems, packaging machines, material handling equipment, and other industrial machinery where controlled motion and high gear ratios are necessary.

- Automotive Systems: Screw gears have applications in automotive systems, particularly in steering mechanisms. They are used in worm and sector steering gears to convert the rotational motion of the steering wheel into the linear motion required for turning the vehicle’s wheels. The self-locking property of screw gears is advantageous in maintaining the position of the wheels after steering input.

- Elevators and Lifts: Screw gears are utilized in elevator systems and lifts for vertical transportation. They are commonly employed in the elevator hoisting mechanism, where the rotational motion of the motor is converted into vertical movement. The high gear reduction ratio of screw gears allows for controlled and precise lifting operations.

- Valve Actuators: Screw gears find applications in valve actuators, which are used to control the opening and closing of valves in various industries. By converting the rotational motion of an electric or manual input into linear motion, screw gears enable precise positioning of valve stems. This allows for accurate flow control in fluid systems, such as water treatment plants, oil refineries, and chemical processing facilities.

- Robotics and Automation: Screw gears play a vital role in robotics and automation systems. They are employed in robot joints and robotic arm mechanisms to provide precise movement and positioning. Screw gears allow for controlled and repeatable motion, making them suitable for applications that require accurate manipulation, such as assembly lines, pick-and-place machines, and robotic surgery systems.

- Camera and Optics Systems: Screw gears are used in camera and optics systems to control focus, zoom, and aperture adjustments. They are commonly found in camera lenses and telescope mechanisms. The fine and precise movement provided by screw gears enables accurate focusing and zooming, facilitating high-quality image capture and precise optical alignment.

- Medical Equipment: Screw gears have applications in medical equipment where controlled and precise movement is necessary. They are used in surgical robots, prosthetic limbs, medical imaging devices, and other medical instruments that require accurate motion control and positioning. The self-locking characteristic of screw gears is particularly advantageous in maintaining stable positions and preventing undesired movement.

- Security Systems: Screw gears are employed in security systems, such as combination locks and safes. They provide the mechanical advantage required to rotate the locking mechanisms and ensure secure operation. The self-locking property of screw gears adds an extra layer of security by preventing unauthorized access through reverse rotation or manipulation.

These are just a few examples of the diverse applications of screw gears. Their ability to provide high gear ratios, precise motion control, and self-locking capabilities makes them valuable in various industries where efficient power transmission, accurate positioning, and controlled movement are essential.

editor by CX 2023-09-04